Line Blind : Introduction

Line Blind : Introduction

What is Line blind valves ? |

||

|

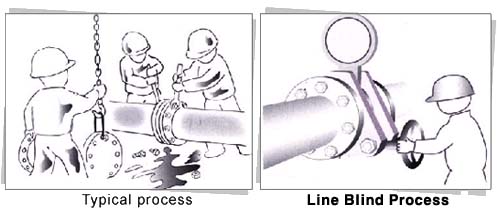

Line blinding has been used to pipelines in various industries wherever either

positive shutoff is most concerned or full flow should be achieved without

pressure drop.

The Line Blind Valves incorporating a touch and

simple design has been developed to provide absolute shut-off, quick opertion

and trouble-free service with minimal maintenance. |

||

|

|

||

|

Why choose Line blind valves ? |

|

|

|

Quick blind valves have the

successful combination of two essential criteria- |

|

|

|

Cost effectiveness |

||||||||||||||||||||||||||

|

Necessary time for blinding or deblinding

-

time saving for draining and line cooling is not included

|

||||||||||||||||||||||||||

|

Products |

|||||||||||||||

| |||||||||||||||

|

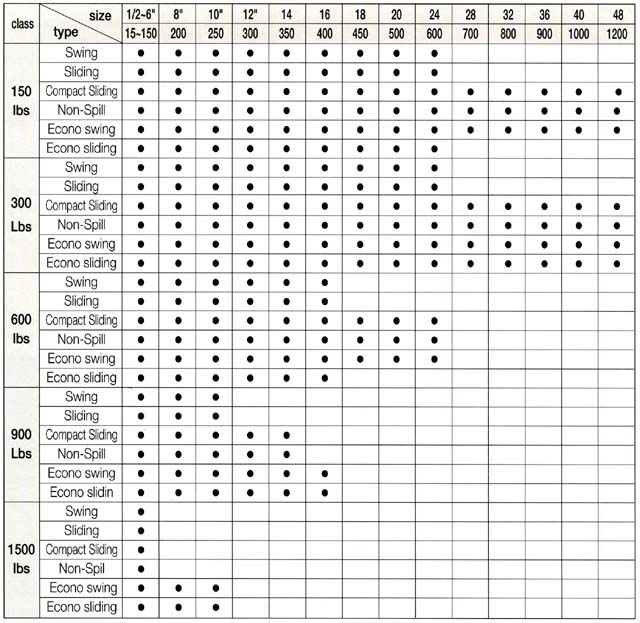

Product Range |

|||||||||||||||

|

| |||

.gif)